ECM - Electrochemical Migration explained

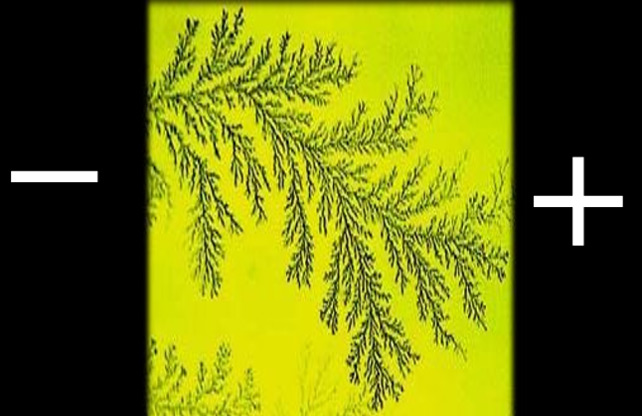

The term ECM, electro-chemical migration, is a corrosion process driven by an electric field. The presence of an electric field makes an enormous difference compared to ordinary corrosion. Ordinarily the residues and materials used on electronic assemblies will not typically lead to corrosion, however the application of an electric field and this innocuous material set can lead to ECM and failure. ECM is very much an electronic assembly issue. The classical ECM failure seen in SIR testing is the formation of a dendrite, as shown below. The fern like dendrite structure grows from the negative cathode towards the anode.

For ECM to occur three important parts must be present, an electric field, a water layer and ionic species. The condition of an electric field is clearly readily met on an electronic assembly. A water film can occur by exposure to liquid water, condensation, or the absorption of a thin water layer. Exposure to liquid water is typically prevented by enclosures, condensation effects are tackled by the use of conformal coatings. The effects of condensation testing is still in its infancy. It is the effects of adsorbed water that SIR studies typically address. With the SIR test environments, 40°C/90%RH and 85°C/85%RH, the water layer thickness is typically ≤100nm. It is within this thin water film that ECM operates. The third and last part are residues that lead to ions being formed as the residues dissolve in the water film. These dissolved ions migrate under the electric field, contributing to the corrosion process and failure.

J Std 001 Appendix C introduces “Objective Evidence” in the context of a failure mechanism that can occur on electronic assemblies. Of concern are residues and contaminants left on the surface of the circuit assembly by the manufacturing process. When in use a circuit assembly will be powered up, it may be in a humid environment, and these two factors with the residues may lead to corrosion, which can lead to electro-chemical migration and the development of a fault, a short circuit. At this point the circuit assembly has failed and it is removed from service. Short circuits produced by ECM are fragile and can disappear when extracted from the use environment, and are a significant contributor to no fault found when inspected as a field return.

Testing of electronic assemblies to ensure robustness in terms of susceptibility to ECM has always been a part of J Std 001. In the past the ROSE test was used, and there was a pass/fail limit of 1.56µg/cm² NaCl (equivalent), the whole test has now been removed. The ROSE test is not sensitive to all the possible causes of ECM, and the pass/fail limit is an arbitrary number, and hence its removal. What has replaced this is not a prescriptive test, but the main stay of OE is now the SIR test.

The Root Causes

Chemistry is involved in many of the steps of electronics manufacturing, including: the application of reactive materials, thermal processing of materials, and cleaning. There are organic and non-organic materials used in the construct of an electronics assembly, and a range of acids and solvents used in the processing to manufacture assemblies. This cocktail must be rendered harmless and robust when manufacturing is complete.

Residues can be acid or alkali based, salts or of concern, neutral chemistries that are hygroscopic that thicken the adsorbed water film. In the presence of water if a residue dissociates to form ions then these will be pulled to the matching electrode. Potentially many chemical cells can be formed on the surface of the electronic assembly. Each cell contains three important parts: the anode and cathode, and the electrolyte. The electrolyte forms in the adsorbed water film and will contain ions from the residues. Positively charged ions, cations, migrate to the cathode and negatively charged ions, anions, migrate to the anode. The anode is hence subject to attack by the migrating anions, plus any corrosive species that were left there by the assembly process. Clearly dissolution by corrosive attack of any metal part is far from ideal. However, this problem is exacerbated by the dissolved anode material ionising in this process to become cations, where they now diffuse to the cathode. When a cation reaches the cathode it gives up its charge, and no longer an ion it deposits onto the cathode. As this process continues, material continues to build on the cathode, growing back to the anode. This structure can grow in a fern like structure to become a dendrite. The total process is therefore the creation and migration of ions under an electric field, which potentially will lead to a circuit failure by the growth of dendrites. This is the electro-chemical migration (ECM) phenomenon, and it is a particularly electronics assembly issue.

There is a caveat that the presence of ionic residues are not a strict requirement, in that the water film can absorb gases that will dissociate and ionise and provide a source of conduction in the water film. Carbon dioxide is such an example.

Characterisation

There are two approaches referred to in J Std 001, SIR and Ion Chromatography. IC is used to measure ionic residues. This is useful when diagnosing residue problems and identifying potential sources, but the IC technique measures the whole board and there is no location information. So we cannot associate a IC signal of a residue with any specific area or component. The IC value (weight) of an ion also cannot be attributed to a pass fail level.

The SIR technique does have a pass fail level from J Std 001, this is 100GΩ. This resistance correlates directly to a circuit function, since no signal or power line should see a leakage current. Hence, a range of component styles with different feature sizes and entrapment potentials can be evaluated on a single SIR test board.