PICT Explained

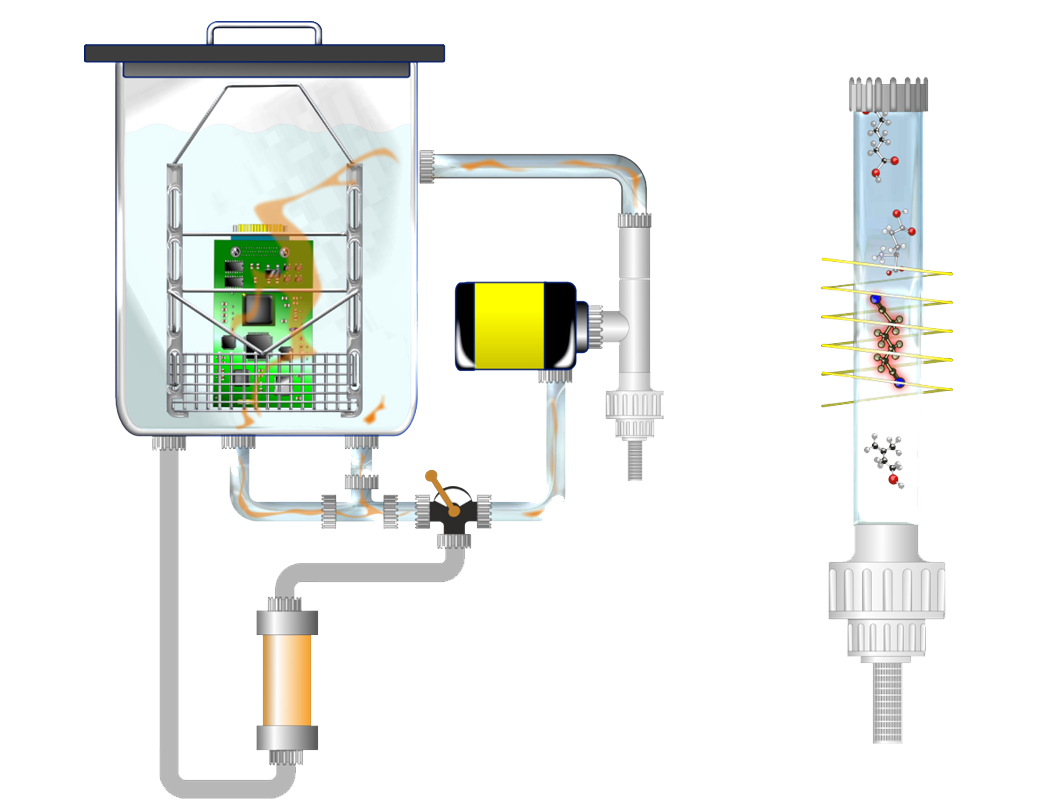

The regular demonstration of quality and meeting OE is to be achieved using the Solvent Extraction Conductivity (SEC) technique. This instrument has been implemented in the Process ionic Contamination Testing (PICT) test, which can be found at IEC 61189-5-504. A typical arrangement of a SEC instrument is shown below, with an exploded view of the measurement cell.

The figure shows the key elements: the tank that holds the product being tested, the circulating pump, a two-way valve, a resin column that deionises the circulating fluid, and the measurement cell, which is shown in an exploded view on the right. The figure

provides a pictorial visualisation of contamination being removed from the product and passing through the measurement cell.

Whereas a qualification with SIR can be broken down into the assembly stages and provide data on specific components the PICT test combines all residues into a single measurement for a product assembly. The SIR test takes a week, the PICT test takes 15 minutes or less.

Following qualification of a product using SIR, this optimised and well characterised product board can be tested in the PICT test, and the residue measurement can be taken as a reference value for this product. Hence, every product will have its specific PICT pass/fail limit.

There is an important distinction between the PICT test and its predecessor the ROSE test, described in IPC-TM-650 Method 2.3.25. Both the ROSE and IC test methods assume that they have removed all of the harmful residues, and hence the measurement correlates with the total residues. This is an impossibility, as entrapment and capillarity effects will prevent all residues being removed. In the PICT test there is no assumption that all residues have to removed, rather the requirement is that the residues that are removed are done reproducible in every test. It is this very approach that is described next.

In 2015, GEN3 was approached by Robert Bosch, who were being required to meet the 1.56µg/cm2 NaCl requirement. This led to an extended research effort ultimately resulting in a joint research paper: Process Control of Ionic Contamination Achieving 6-Sigma Criteria in The Assembly of Electronic Circuits.

This effort resulted in a new International Standard IEC 61189-5-504 Process Ionic Contamination Testing – PICT, published in 2020.

This document represents the most rigorous review of the test method and highlights several deficiencies in the IPC-TM-650 Method 2.6.3.5.