Why is OE an issue today?

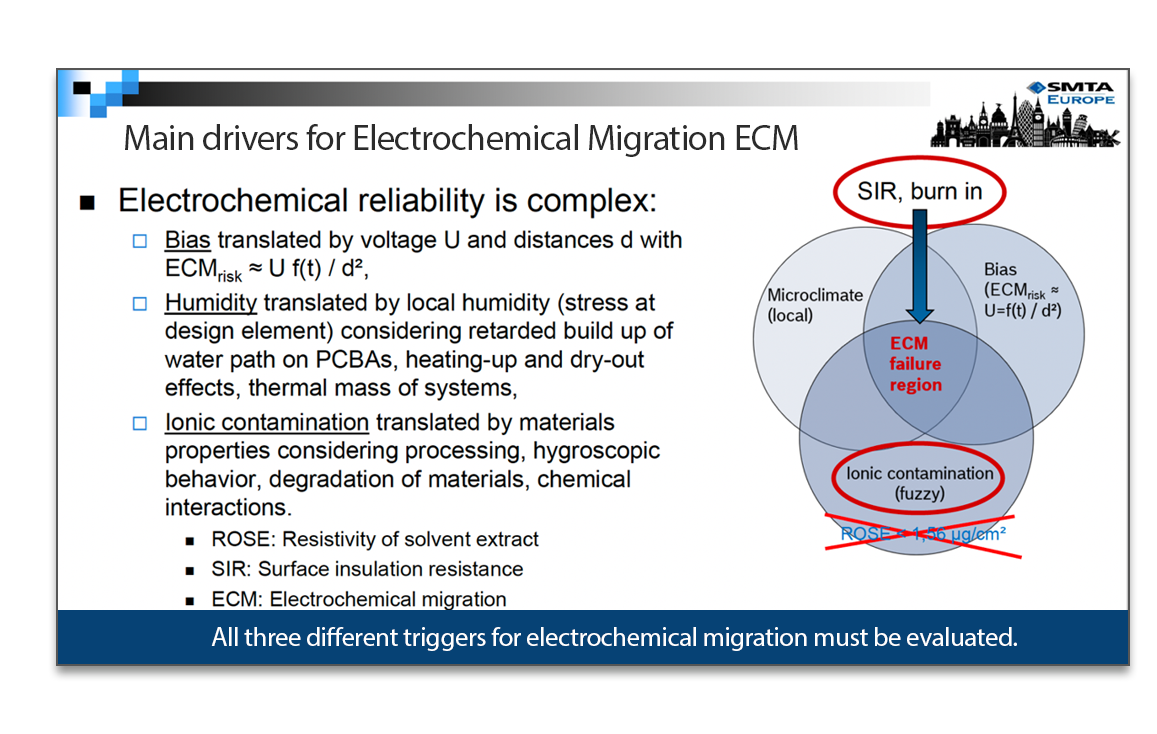

OE is now the metric of establishing quality as the ROSE test value of 1.56µg/cm² fails to represent the wide range of componentry and processes used today. The original value, 10µg/inch² and then converted to 1.56µg/cm², was a stake in the ground, and agreed to be representative of product in the 1980’s. The ROSE test and the 1.56µg/cm² assumes that a representative contamination budget has been removed and that this value will correlate to ECM susceptibility. This is not the case.

With PCB technologies extending down to 75µm pitch, above 1kV, and above 5GHz, the use of the ROSE test is no longer applicable as an arbiter of quality or fitness for purpose, with it failing to detect critical issues in circuit assemblies. Bottom terminated components present a cleaning challenge, for which the ROSE test is ill equipped.

There is a more fundamental problem that the 1.56µg/cm² from ROSE test does not in itself predict reliability. What does it mean if a board has 1.56µg/cm² of NaCl equivalent over its entirety?

This is why the SIR test measuring isolation resistance at the component level, is so effective. Isolation resistance does correlate very well with reliability and quality.

With the ever-diminishing size of electronic circuits, increased packaging density and much reduced conductor separation, coupled with hostile operating environments has greatly increased both the risk and incidence of corrosion especially electrochemical migration.

Residues are inevitable from any assembly build process, in some cases a cleaning stage is used in others it is not. For both the no-clean and cleaning processes there is a requirement to demonstrate that residues are below a certain level, and that an ECM failure has vanishingly small probability of occurring. Hence the need to produce “Objective Evidence” that demonstrates, using test data, that circuit assembly meets a requirement where residues are not detrimental.

A significant deficiency within the changes made to the JSTD001 is that it makes no provision for the majority of the industry who operate a “No clean” process. Whether cleaning is done or not, the problem prevails. This is best illustrated in the presentation given by Dr Lothar Henneken of Robert Bosch GmbH at the SMTA Electronics in Harsh Environments, Amsterdam, 17-19 May 2022. Note that Robert Bosch Automotive operate a no-clean process: